Tufted rugs are a popular choice for custom choices.

They combine craftsmanship, style, and durability with a faster, more cost-effective production process than traditional hand-knotted rugs.

Because of the tufting technique, custom tufted rugs have become an ideal option for business buyers in hospitality, office, and retail settings.

This friendly guide will help you understand the process from start to finish.

Design Phase

Design Creation

A custom tufted rug begins with a design file.

- The design file can be a photo, a graphic design image, a CAD drawing, or anything you can visualize your desired graphics and patterns.

- Tufted rug customizations can include company logos, custom patterns, artistic designs, or any graphic designs you provide.

You can provide your images, we’ll transform your image into a tufted rug ready design.

The beauty of tufted rugs is that almost any design can be realized, from geometric patterns to photorealistic images.

Digital Preparation

After we receive your design file, our technical team optimizes it for tufting.

The things we will do include:

- Reduce the number of colors

- Adjust colors to match available yarns

- Remove details that are too small to do tufting

- Scale dimensions to fit your space requirements

This preparation stage is crucial for achieving the best possible results when your design moves to production.

During this stage, we will send you preview or multiple previews for the rug’s visual effects.

Design Transfer

After digital preparation, our industrial printer system transfers your design directly onto the backing fabric with exceptional accuracy.

This is particularly crucial for intricate patterns and smooth color gradients.

Unlike hand-traced designs that may contain slight inconsistencies, our printer creates perfect guidelines for our artisans to follow

It captures every nuance of your original concept down to the millimeter.

Printing Advantages

Traditional marker methods often result in approximations of complex designs, but our printing technology captures every subtle detail and color specification.

These printed guidelines act as a detailed roadmap for our artisans, showing exactly which colors go where and eliminating guesswork.

For designs with multiple color transitions or detailed patterns, this printing method preserves all the nuances that make your design unique, ensuring that your final rug will match your vision perfectly.

Materials Selection

Yarn Types

One of the first decisions in making a tufted rug is choosing the yarn material.

The yarn determines the rug’s texture, appearance, performance, and also cost.

New Zealand Wool

This is the most common yarn choice for the majority of our custom rug customers during our 20+ years’ experience.

If you are not sure which yarn to pick, then pick this yarn type.

It has many benefits, including but not limited to the following ones:

- Natural fiber renowned for resilience and softness with a plush, high-quality feel

- Naturally dirt- and stain-resistant due to microscopic scales that repel soil, making cleaning easier

- Excellent durability for high-traffic areas with a lifespan of 5-10 years under normal use

However, it does have one important drawback.

Avoid wool yarn if shedding at the beginning is something you absolutely you can not accept.

Acrylic Fiber

Consider acrylic yarn if cost and shedding are 2 important factors for your consideration.

Acrylic is a synthetic yarn that is designed to mimic wool in softness while being very durable.

It has the benefits as listed below, but not limited to these:

- Holds color exceptionally well without fading, even in areas with direct sunlight

- Stain-resistant and low-shedding from the first day, requiring minimal “break-in” time

Rayon (Art Silk)

Rayon is a plant-based fiber (cellulose) processed to mimic the look of mulberry silk.

Therefore, it has a nickname “artificial silk”, and has a luxurious sheen and smooth, silky texture.

Consider this yarn if you prefer some vibrant colors and you will use this rug for decoration, rather than to sit or walk on it.

- Luxurious sheen and smooth, silky texture that catches and reflects light beautifully

- Colors appear exceptionally bright and lustrous, creating vibrant visual impact

Bamboo Silk

- Viscose derived from bamboo fibers with a gorgeous silk-like shimmer that creates elegant highlights

- Eco-friendly and sustainable material sourced from a rapidly renewable plant

- Extremely soft underfoot with a luxurious, smooth texture

Yarn Preparation

Our team precisely calculates yarn quantities needed for your design, considering pile height, density, and pattern complexity.

Our specialists then prepare and organize each color on professional coning systems, winding the yarn at specific tensions to ensure smooth feeding through our tufting equipment.

This careful preparation prevents any interruptions during the tufting process and maintains consistent texture throughout your rug.

For complex designs with many colors, this organization stage is crucial for efficiency and quality.

Material Selection Tips

Many custom rugs blend materials for optimal results.

- Use wool for the base (providing strength and durability)

- Add rayon or bamboo silk accents (for shine and visual interest) to highlight patterns or create contrast in specific areas.

We’ll help you select the perfect materials based on your design, usage needs, and budget.

For commercial spaces, we might recommend a durable wool/acrylic blend, while for a luxury residential project, a wool base with bamboo silk highlights might create the perfect balance of practicality and elegance.

Frame Setup

Frame Selection

We select an appropriately sized industrial-grade frame for your specific rug dimensions.

Our frames are constructed from heavy-duty steel or aluminum and can accommodate rugs ranging from small 2’x3′ accent pieces to massive 20’x30′ statement rugs.

Each frame is inspected before use to ensure perfect alignment and stability, as even minor imperfections at this stage could affect the final rug quality.

Backing Fabric

Premium backing fabric is secured to the frame as the foundation for your rug. For hand-tufted rugs, we typically use cotton canvas or monk’s cloth due to their strength and ability to maintain tension throughout the tufting process.

These natural fabrics have an open weave that allows the tufting needle to penetrate cleanly while providing enough resistance to hold the yarn firmly in place. The quality of this primary backing is essential – we use only premium-grade materials that won’t stretch or sag during production.

Tensioning Process

We carefully adjust the tension until the backing is drum-tight across the entire frame. This is achieved using specialized clamps and tensioning tools operated by experienced technicians.

The backing must be uniformly taut in all directions – any slack areas would create inconsistencies in tuft density and potentially cause rippling in the finished rug.

Our tensioning process involves multiple adjustments and checks to ensure perfect uniformity. This crucial step ensures consistent density and prevents warping or distortion in the final product.

Stability Check

Once tensioned, each frame undergoes a thorough stability check. Our quality control specialists inspect the entire surface, testing tension at multiple points and securing any areas that need additional reinforcement.

The frame itself is braced and leveled to prevent any shifting during the tufting process. This engineering for stability allows our artisans to work with confidence and precision, resulting in a perfectly even surface ready for your design.

Any compromises at this stage would be visible in the finished rug, so we take extra care to ensure everything is perfect before tufting begins.

Tufting Process

Tufting Techniques

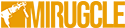

Hand-Tufting Method

Used for most custom one-off designs and higher-end rugs where detail and precision are paramount.

Artisans use a handheld tufting gun to push yarn through the backing fabric while following the printed design.

The tufting gun is a specialized electric tool that rapidly needles yarn into the backing, creating loops at a rate of several stitches per second

Artisans can adjust the gun’s settings to control pile height (typically between 1/2″ to 1″ for residential rugs) and density.

- Our tufting people will work color by color, filling areas according to the pattern – much like “painting by numbers” but with yarn

- Allows for precise details, curves, and intricate motifs that would be difficult or impossible with machine tufting

- Skilled tufters develop techniques to create smooth transitions between colors and maintain consistent density

- The process is labor-intensive but allows complete artistic control – a medium-sized 5’x8′ rug may take 3-5 days of tufting time

- Enables creation of one-of-a-kind pieces with custom colors, sizes, and designs specific to your needs

Machine-Tufting Option

Used for larger orders or rugs with repetitive patterns where consistency is more important than artistic variation.

Automated machines with hundreds of needles operate in unison, tufting many rows simultaneously.

- Computer-controlled systems can follow programmed patterns with precise color placement

- More efficient for high-volume production – can produce in hours what might take days by hand

- Creates consistent, uniform results with perfectly even pile height and density

- Limited in creating organic curves or irregular shapes compared to hand-tufting

- Ideal for commercial projects requiring multiple identical rugs or very large installations

- More economical for larger quantities but requires significant setup time for each unique design

- Modern tufting machines can create sophisticated patterns through computer programming

Pile Types

Cut Pile

We can create cut piles by cutting the yarn loops during or after insertion, resulting in upright yarn ends.

This pile type offers luxurious softness perfect for contemporary designs and comfortable areas like bedrooms.

And it gives a plush, velvety feel underfoot that’s particularly appealing in bare-foot areas.

Ideal for showcasing color transitions and subtle shading in complex designs.

- Available in various heights from low (1/4″) for practical spaces to high (1″+) for luxurious depth

- Shows footprints and vacuum marks more readily, especially in solid colors and plush heights

- Creates a more formal, refined appearance with rich color saturation

- Provides better insulation and sound absorption than loop pile

- Can be finished with different sheering techniques to create various textures

Loop Pile

Yarn loops remain intact, creating a series of small loops across the rug surface.

Loop piles create interesting textures ideal for geometric patterns and contemporary designs.

It is less likely to show footprints or vacuum tracks, maintaining its appearance longer.

Creates a more casual, textural appearance mainly for decoration purposes.

- Can be varied in height to create pattern effects (high-low loop or “sculptured” effects)

- Slightly firmer underfoot compared to cut pile but still comfortable

- May catch on jewelry, pet claws, or sharp objects – not ideal for homes with pets that scratch

- Excellent for creating visual texture and dimension in simpler color palettes

Directional Tufting

Each section is carefully tufted in a specific direction, creating beautiful surface variations that catch light differently throughout the day.

Our artisans plan these directional changes to enhance the design – for example, tufting a background in one direction while tufting a foreground element in another to create subtle contrast even within the same color.

This technique, known as “pile direction,” is similar to the nap in velvet fabric and can dramatically change how the rug looks depending on the viewing angle and lighting conditions.

Skilled tufters use this principle to add depth and dimension to flat designs.

Color Transitions

Our artisans seamlessly transition between colors, ensuring clean lines and smooth gradients exactly as designed.

This requires tremendous skill – each color change involves stopping, changing yarn, and resuming at precisely the right spot. For gradual transitions, our tufters may blend colors by alternating rows or creating a speckled effect where colors meet.

For sharp boundaries, they carefully follow the design lines to create crisp definition.

These transitions are crucial for logos, artistic patterns, and any design with multiple colors.

The precision of these color changes is often what sets apart a professional tufted rug from amateur attempts.

Backing Application

Initial Latex Application

After tufting is complete, we carefully flip the rug and apply a premium latex backing that locks every tuft securely in place.

This adhesive is typically a natural or synthetic rubber compound specially formulated for rug making.

We use a trowel or specialized spreader to ensure an even coating across the entire back surface, working the latex around the base of each tuft to create a strong bond.

The quality of this latex is crucial – we use only professional-grade adhesives that maintain flexibility while providing exceptional holding power.

Latex Function

This critical step transforms your rug from a delicate creation into a durable piece ready for daily use by “freezing” the pattern in place so yarns can’t move or fall out.

Without this backing, the tufts would simply pull out under normal foot traffic.

The latex penetrates slightly into the primary backing fabric, creating a mechanical bond in addition to the adhesive bond.

This dual-securing approach ensures longevity even under heavy use.

Quality latex maintains its flexibility for years without cracking or deteriorating, which is essential for the rug’s lifespan.

Secondary Backing Addition

While the latex is still tacky, we add a professional-grade secondary backing (often sturdy cotton canvas or jute cloth) that covers all the glued yarn ends and gives the rug structural stability and heft.

This backing is carefully rolled onto the latex surface to prevent air bubbles or wrinkles, and pressure is applied to ensure complete adhesion.

The secondary backing creates a smooth surface against your floor and adds significant dimensional stability to prevent curling or warping.

It also provides additional protection against moisture and helps the rug lay flat.

Backing Benefits

The secondary backing provides multiple benefits beyond just covering the latex:

Adds structural integrity that helps the rug maintain its shape under furniture and foot traffic

Creates a smooth finish that protects your floors from the rough latex surface

Prevents yarn shedding by securing the tufts from behind.

Adds weight and body to the rug, helping it stay in place on your floor

Provides a clean, finished appearance to the back of the rug.

Extends the rug’s lifespan by reinforcing the primary backing

Helps distribute tension evenly across the rug when it’s moved or cleaned

Curing Time

We allow proper curing time for all backing materials in a controlled environment with optimal temperature and humidity.

This curing period typically takes 24-48 hours depending on conditions and is essential for developing maximum bond strength.

During this time, the latex transitions from tacky to fully set, creating permanent bonds with both the yarn tufts and the secondary backing.

Rushing this process would compromise the rug’s structural integrity, so we ensure each rug receives the full curing time required.

This patience pays off in a rug that maintains its shape and structure for years to come.

Edge Finishing

Edge Options

Binding

Classic fabric tape (typically cotton, polyester, or a blend) is folded over the rug edge and securely sewn in place using heavy-duty thread and specialized sewing equipment. This creates a clean, tailored appearance similar to the hem on clothing. Binding protects the rug edge from fraying and provides a durable finish that stands up to vacuuming and regular use. We offer binding in matching or contrasting colors to either blend seamlessly with your rug or create a decorative border effect. Binding is particularly recommended for rugs in high-traffic areas as it provides superior edge protection.

Serging

A technique where yarn is tightly wrapped around the edge in a continuous spiral pattern, creating a thick, rope-like border.

Our serging machines use heavy-duty yarn that matches or complements your rug design to create this durable edge finish.

Serging offers excellent durability while providing a more casual, textural appearance than binding. This finish works particularly well with more rustic or relaxed designs and creates a subtle visual frame around your rug. The technique is adapted from carpet finishing and provides excellent resistance to wear along the edges.

Fringing

Decorative fringe elements added for character and traditional styling.

Fringe options range from simple yarn extensions to elaborate knotted or braided designs. While tufted rugs don’t naturally produce fringe (unlike hand-knotted rugs where fringe is part of the structural warp threads), we can attach decorative fringe for aesthetic purposes.

These fringe elements add movement and visual interest, particularly in traditional or transitional rug styles. We secure fringe with both stitching and adhesive to ensure durability, though fringe is generally recommended for lower-traffic areas.

Edge Execution

Each edge finishing method is carefully executed for both beauty and longevity, with special attention to corners and transitions.

Our finishing specialists use precision techniques to create perfect mitered corners where binding meets, ensure even tension in serging to prevent rippling, and secure fringe attachments that won’t come loose.

The quality of these edge finishes significantly impacts both the appearance and lifespan of your rug – amateur edge work quickly shows wear, while our professional finishing stands the test of time.

We take extra care with non-rectangular shapes, where edge finishing becomes even more challenging and requires specialized techniques to follow curves and angles perfectly.

Surface Finishing

Shearing Process

After the backing has fully cured, we return to the rug’s face for final finishing.

We use professional shearing equipment – essentially specialized electric clippers with precise height adjustment – to create a perfectly even surface height across the entire rug.

This process reveals the crisp definition of your design by removing any inconsistencies in pile height that occurred during tufting.

Our shearing technicians make multiple passes, gradually approaching the final height to avoid cutting too low.

This precision technique ensures a flawlessly smooth surface while preserving the full density and plushness of the pile.

Surface Uniformity

Shearing evens out any yarn that was tufted unevenly and gives a smooth, velvety feel for cut piles or uniform loop height for loop piles.

Even expert tufters create slight variations in pile height during the tufting process, and shearing corrects these inconsistencies. This uniformity is not just aesthetic – it ensures your rug will wear evenly over time rather than showing premature wear in taller areas.

The shearing process also removes any loose fibers or “flyaway” yarns that might otherwise shed onto your floor during the rug’s early use.

Hand-Carving Details

For ornate designs, our skilled artisans use special scissors or carving tools to outline design elements, creating lines or lowering backgrounds to make motifs stand out in relief. This hand-carving requires exceptional precision and artistic judgment. The carver carefully follows the design contours, trimming the pile to different heights to create definition and emphasis. This technique is particularly effective for floral patterns, logos with text, or any design where you want certain elements to visually “pop” from the background. Carving adds a dimension of craftsmanship that distinguishes fine tufted rugs from mass-produced alternatives.

Carving Effects

Carving can create remarkable visual effects in your rug:

- 3D relief patterns where design elements appear to rise from the background

- Ridges and bevels that catch light and create shadow lines, enhancing design definition

- Embossed details that add tactile interest and sophisticated dimensionality

- Textural contrast between higher and lower areas, creating visual depth

- Outlined elements that stand out clearly, even in tone-on-tone designs

- Sculpted effects that mimic the look of hand-carved wood or stone

- Enhanced definition for text or logo elements in corporate or branded rugs

These carved details add rich texture and visual interest that transforms a flat design into a multi-dimensional art piece.

The carving skill is developed over years of practice and represents one of the highest forms of rug craftsmanship.

Quality Inspection

Our quality control team carefully examines your rug from multiple angles and under different lighting conditions, checking for consistent pile height, design accuracy, color fidelity, and structural integrity.

They verify that all edges are finished perfectly, the backing is securely attached, and the design matches the approved pattern.

Any imperfections are marked for correction before the rug leaves our workshop.

This inspection includes checking for consistent density, secure tufts, proper pile direction, and perfect color placement.

Only rugs that pass this rigorous inspection move to the final cleaning stage.

Final Grooming

After all shearing, carving, and inspection steps are complete, we perform a final grooming to prepare your rug for delivery.

This includes carefully brushing the pile to align fibers in the intended direction, detailed edge trimming to remove any stray threads, and spot-checking for any areas that need touch-up.

For rugs with multiple pile heights or carved elements, we use specialized brushes to groom each area appropriately without disturbing the intentional height variations.

This final attention to detail ensures your rug arrives looking its absolute best, with the pile perfectly oriented and the surface immaculately presented.

Cleaning & Preparation

Vacuum Process

We thoroughly vacuum the rug using professional-grade equipment with adjustable suction and brush settings appropriate for your specific pile type and height. This removes any loose fibers, dust, and small debris generated during the manufacturing process. Multiple passes are made from different directions to ensure complete cleaning, and special attention is given to carved areas and transitions between different pile heights. This vacuuming is more intensive than regular home maintenance and prepares the rug for its final inspection.

Final Inspection

Each rug undergoes a comprehensive final inspection before packaging, checking for:

- Perfect color matching against the original design specifications

- Uniform pile height across similar areas

- Secure backing with no loose sections or visible glue

- Clean, precise edge finishing with no loose threads

- Correct dimensions within our tight tolerance standards (typically ±0.5%)

- Proper execution of all design elements, including accurate color placement

- Perfectly flat lay without rippling, buckling, or curling

- Complete removal of any manufacturing marks or residue

- Structural integrity with no weaknesses or defects

Only after passing this detailed inspection is your rug approved for packaging and delivery.

Packing & Shipping

Rolling Technique

Each rug is professionally rolled around a sturdy tube in the direction of the pile to prevent creasing. We use acid-free paper between layers for large rugs to prevent color transfer or pile compression during shipping. The rolling is done gradually with even tension to avoid creating stress points or distorting the rug’s shape. This method, rather than folding, ensures your rug arrives without creases that might be difficult to remove. The core tube is sized appropriately for your specific rug dimensions to create the optimal roll diameter.

Protective Wrapping

We wrap the rolled rug in multiple layers of protection:

An inner layer of plastic sheeting creates a moisture barrier

A middle layer of heavy-duty plastic provides puncture resistance

An outer layer of protective covering guards against abrasion and tearing

End caps secure the tube ends to prevent shifting and edge damage

Sealed with heavy-duty tape that won’t come loose during transit

This multi-layer approach guards against moisture, dust, and physical damage during transportation, ensuring your rug arrives in the same pristine condition as when it left our workshop.

Size-Specific Protection

For larger rugs, we take additional precautions:

- Use reinforced tubes with greater wall thickness to prevent bending

- Add extra protection at stress points like corners and edges

- Secure the roll with bands at regular intervals to prevent shifting

- Provide custom-sized crates for extremely large or valuable pieces

- Use specialized handling instructions for delivery personnel

These additional measures ensure that even oversized rugs arrive without damage, as larger pieces are more vulnerable to handling issues during transportation.

Shipment Tracking

Every package receives a comprehensive tracking system:

- Detailed documentation of the rug specifications and condition before shipping

- Real-time tracking information so you can monitor your rug’s journey

- Insurance coverage appropriate to the rug’s value

- Delivery appointment scheduling to ensure someone is available to receive the rug

- Installation recommendations and initial care instructions included with delivery

This attention to shipping details ensures your custom creation arrives in pristine condition, ready to transform your space. We coordinate with you to schedule delivery at a convenient time and can provide unpacking assistance when needed.

Making Your Decision

Custom tufted rugs offer remarkable design flexibility:

- Almost any pattern or image you can imagine can be translated into a rug

- Perfect for logos, artwork, or specific design elements that need to match existing décor

- Can incorporate curves, organic shapes, and fluid designs that would be difficult in other rug types

- Can combine different pile heights and techniques in a single rug for textural interest

- Allows for designs that would be prohibitively expensive in hand-knotted constructions

This flexibility makes tufted rugs ideal for designers seeking to create truly custom floor coverings.

Our team is ready to guide you through each step of creating your perfect rug, from initial design to final delivery.

Contact us for your perfect tufted rug!